Key Fact #1

Disinfection of water-bearing systems.

Key Fact #2

Permeation of biofilm.

Key Fact #3

Natural enhancement of active substances.

BIOFILMS

as starting point

for microbacterial growth.

The major proportion of microorganisms lives stationary on surfaces. Under normal environmental conditions they start to form biofilms. Biofilms are a gooey substance known as an extracellular polymeric substance (EPS). Microorganisms remain metabolically active in biofilms where they are protected against physical and chemical damage.

Biofilms are ubiquitous in nature, yet, especially frequent in industrial, technical, medical and manufacturing water supply systems. Examples are cooling towers, water supply elements of medical devices, and household water supplies.

A number of different antimicrobial agents and technical systems have been devised for water disinfection or control of microbial growth. Many commercially available active agents are expensive, toxic to humans and aquatic life, non-biodegradable and ecologically questionable.

Therefore, there is a growing demand for natural, ecologically and economically favourable antimicrobial agents. However, such natural agents are often poorly water-soluble, may have an obnoxious smell or taste, or are not able to penetrate mature biofilms adequately at technically achievable concentrations.

Enhancement of active substances

in Biofilms

Hydro L.O.G.® is based on L.O.G. Technology®. It is composed of micelle-forming solutes from plant extracts, an emulsifier, water and hydrogen peroxide.

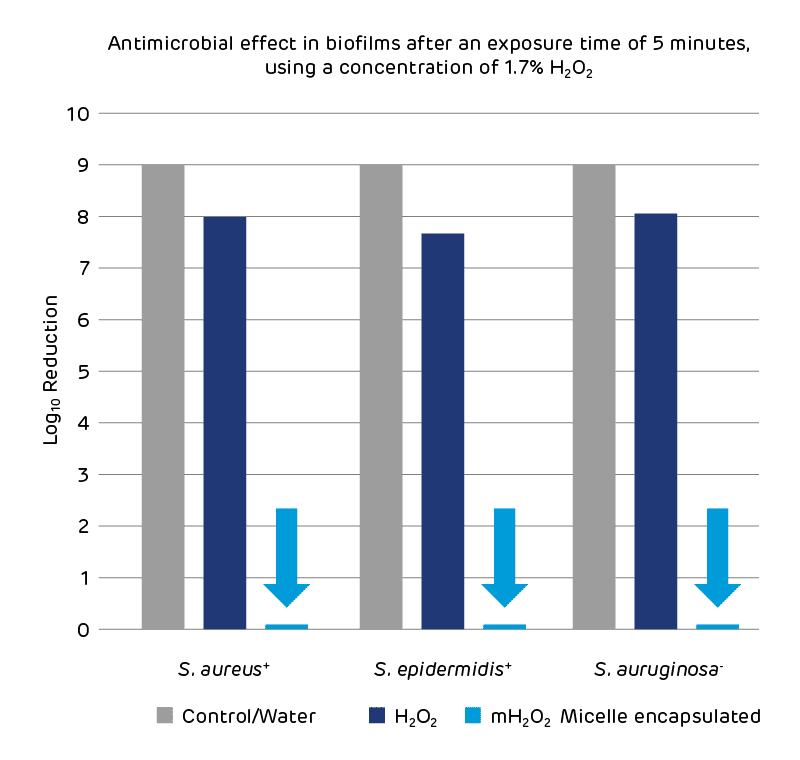

Penetration of slimy structures is facilitated by packing H2O2 into micelles. By this means, the active agent is transported through the biofilm, the micelle merges with the bacterial envelope and hydrogen peroxide can be directly released at site. Application of L.O.G. Technology® allows a more efficient use of active agents, higher disinfection rates and an improved environmental compatibility.

HYDRO L.O.G.® demonstrates a significantly improved antibacterial efficacy compared to non-micelle preparations of the same antimicrobial agent.(1)

(1) Assadian O et al., Biofouling 2020, 36(5):576-586

Unique Technology. Quick sucess.

OPERATING PRINCIPLE

01

02

03

04

Viruses and bacteria are rendered harmless.

ADVANTAGES

ARE EMINENT.

Unique technology. Quick sucess.

Sustainable and biodegradable components

Short exposure times

Excellent material compatibility due to low concentrations of the active substance

SCOPE OF APPLICATION

SCOPE OF APPLICATION

INDUSTRIAL

FACILITY

MEDICAL

FOOD&BEVERAGE

AGRICULTURAL

Mordant, Seed treatment, Soil treatment, Storage

FARMING

Reduction in biofilms